At Omicron, our priority is to offer a first-class precision machining service to our clients, and to do so, we are fully committed to the use of cutting-edge technology in our processes.

Over 57 years’ experience in the sector has led us to be able to adapt to the market, improving our abilities and capacities every day, and striving to find versatility in the production and machining of large parts according to specifications.

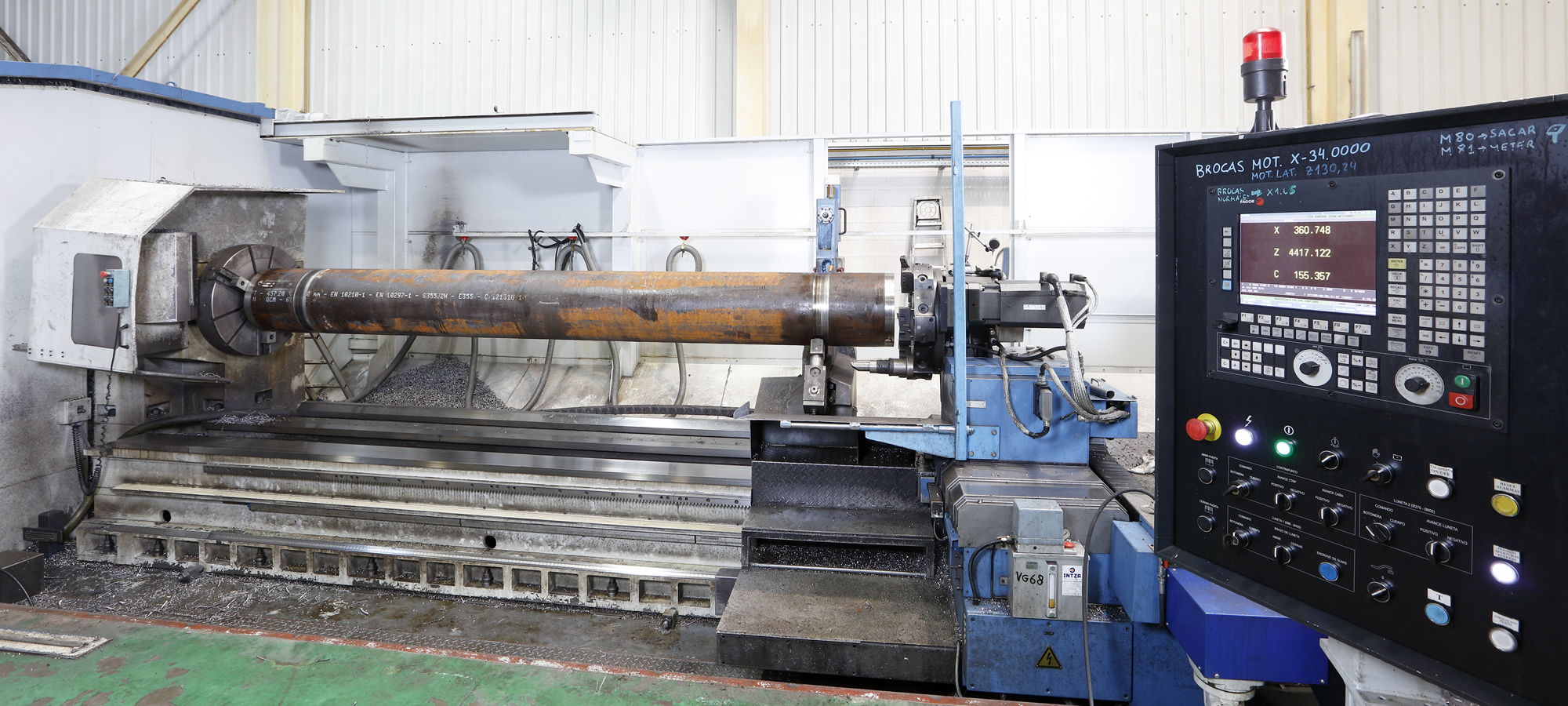

We have a complete line of CNC lathes and parallel lathes that enable us to offer a wide variety of options in the process of machining parts according to specifications. Here is a list of the lathes we work with.

RECONVERTED BOST LATHE

2 CMZ 30 CNC LATHES

CMZ 35 CNC LATHE

Mod. BOST LATHE T3-1200

Mod. GURUTZPE LATHE 1000/2

Mod. DANOBAT LATHE NI-650

DANOBAT-LEALDE Mod. LATHE TCN-12 EP750

At Omicrón we are committed to quality, which is why we have as a priority quality management objective the permanent improvement of all our processes and activities, consult our quality policy.

AMUTIO-CAZENEUVE Mod. LATHE HB-575

AMUTIO-CAZENEUVE Mod. LATHE HB-575

AMUTIO-CAZENEUVE Mod. LATHE HB-575

AMUTIO Mod. LATHE HB-725 (DELTECO)

ETXEA/BOST Mod. LATHE DN-500

ECHEA-9000 Mod. LATHE RA 360

GURUTZPE BT LATHE

TOS LATHE

GURUTZPE LATHE

SCULFORT SUPERCAP 500 LATHE

TOS SU 125 H LATHE

Our precision machining and lapping of parts on drawings or samples has been certified under the ISO 9001:2015 Quality Management System standard for over 15 years

We also have a grinding machine, a Sunnen HTC-8300W-01 lapping machine, that enables us to work on the grinding and lapping of interiors of large parts with maximum precision.

SUNNEN HTC-8300W-01 HORIZONTAL HONING MACHINE

Innovation and technology have been key to our growth throughout our history. Our facilities are divided into two buildings covering a total of 1,700m2. We have a technical office to study every project we take on and to offer personalised solutions to each client. This allows us to accelerate the preparation of plans and programmes, and to streamline quality assured production.

One of our principles is to achieve the highest possible quality in each and every part we produce. Our team of qualified professionals, combined with cutting-edge measuring equipment, enable us to have complete control over each and every part we produce. So, using these tools, we are able to send our clients the corresponding measurement reports in each project: callipers, exterior and interior micrometers, surface roughness testers, ultrasound devices and gauges for screw thread control.

+34 943 691 662

Asteasuko Industrialdea, B Gunea, 40

20159 Asteasu (Guipúzcoa)

?